Vertical Transfer Presses For Bullets

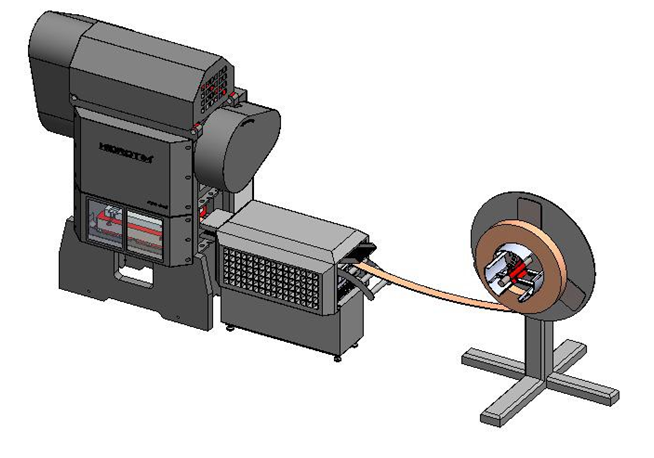

CUP PRESS

Purpose:The manufacturing process involves the production of cups from strips, which are

essential components used in manufacturing cartridge cases and bullets for small arm

ammunitions.

Adjustable tool holder block, Automatic lubrication system, Strip decoiler, Strip guide

way,Scrap cut-off device or scrap winder device,The coolant lubrication reservoir.

All system work with PLC control

Motor power: 20 KW

Air Pressure: 6 bar

DRAWING PRESS

Vertical press for drawings, operations on small and medium caliber ammunitions cartridge

cases.

Operations: Working slide actuated by crankshaft connecting rod assembly and controlled

by an

electro pneumatic clutch brake.

Case feeding, Adjustable tool holder block,Automatic lubrication system

Standard force: 60 tons

Usage: For all drawing of cases

Installed power: 20 KW

Air Pressure: 6 bar

All system work with PLC control

FORMING PRESS

Vertical press is for intending, heading & fire hole on small and medium calibers ammunition

cartridge cases.

Operations: Working slide actuated by crankshaft connecting rod assembly and controlled

by an

electro pneumatic clutch brake.

Case feeding, Automatic lubrication system

Standard force: 80 tons

Installed power: 30 KW

Air Pressure: 6 bar

All system work with PLC control

FULL FORM PRESS

Vertical press is for tapering & necking on small and medium calibers ammunition cartridge case.

Operations: Working slide actuated by crankshaft connecting rod assembly and controlled by an

electro pneumatic clutch brake.

Case feeding, Automatic lubrication system

Standard force: 60 tons

Installed power: 30 KW

Air Pressure: 6 bar

All system work with PLC control